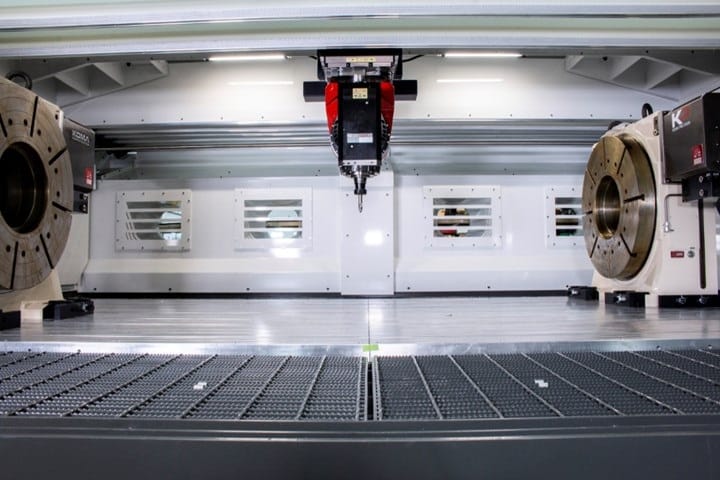

For start-ups, choosing the right manufacturing process is crucial in bringing innovative products to market while managing tight budgets. As advanced machining technologies like 5-axis CNC milling become more widely available, start-ups may wonder whether these services are affordable and worth the investment.

While 5-axis CNC milling offers exceptional precision and versatility, it’s often perceived as an expensive option reserved for large companies or complex industries. However, with careful planning and a clear understanding of its benefits, 5-axis CNC milling can be an affordable solution, even for start-up end users. You may be wondering how. Let’s check out some factors influencing the affordability of 5-axis CNC services and practical tips for start-ups looking to take advantage of this powerful technology.

Key Considerations when Choosing 5-Axis CNC Mill Service for Start-up End Users

Several factors determine overall costs when deciding whether 5-axis CNC milling is affordable. Start-ups should weigh these considerations to make informed decisions that balance quality and budget:

Project Complexity

5-axis CNC milling excels at producing complex, multi-faceted parts. Unlike 3-axis machines, which require multiple setups to work on different angles of a part, a 5-axis machine can handle the entire process in one go. This is particularly useful for intricate designs that require high precision. While the upfront cost of 5-axis machining may be higher, the reduction in setup time and increased accuracy can make it more cost-effective in the long run, especially for projects with detailed, complex geometries.

Production Volume

For start-ups working with low production volumes, you must understand how this affects the cost per unit. CNC 5-axis milling typically involves a higher setup cost than simpler machining processes. Therefore, the per-part cost can be high for small quantities. However, if your project involves low-volume, high-mix production, the efficiency of 5-axis machines could offset these initial costs. Start-ups can benefit from the machine’s ability to complete complex parts in fewer steps. This lowers labor costs and reduces production time, even in smaller batches.

Material Selection

Tougher materials such as titanium, steel, or alloys require more cutting force and longer machine time, which can increase costs. However, using a softer, more machine-friendly material can reduce the cost per part. For start-ups, you must find the right material that balances durability, performance, and affordability. Doing this give you a higher chance of making the overall costs manageable while benefiting from the precision of 5-axis milling.

Tolerances and Precision

One of the main advantages of 5-axis CNC milling is its ability to achieve tight tolerances and high precision. However, the tighter the tolerance required, the more time and effort it takes to achieve, which can drive up costs. Start-ups should carefully evaluate their projects and determine whether ultra-precise tolerances are necessary. In many cases, a slightly relaxed tolerance will still meet the design requirements while reducing the machining cost.

Service Provider Expertise

Experienced CNC service providers are more likely to optimize machining processes to reduce material waste and improve turnaround times. Start-ups should look for providers with a track record of working on similar projects and offering solutions to minimize costs. A well-established provider may even help refine the design to make it more cost-effective to machine without sacrificing quality.

Turnaround Time

Start-ups operate in a fast-paced world. Therefore, time is often of the essence. Many CNC service providers offer expedited services, but these usually come with a higher price tag. However, with the efficiency of 5-axis machines, parts can often be produced faster without the need for rush services. This is especially the case when producing complex parts that would take longer with traditional methods. Start-ups should plan ahead and communicate clear timelines to avoid unnecessary costs associated with last-minute orders.

Why 5-Axis CNC Mill Service in Product Development?

For start-up end users, 5-axis CNC milling offers numerous advantages during product development. Its precision, flexibility, and speed make it an excellent choice for turning ideas into reality.

Here’s why it stands out during this critical stage:

Flexibility for Complex Parts

Product development often involves creating complex prototypes with unusual shapes or features. With 5-axis CNC milling, the machine can move in five directions, making it easier to machine complex geometries in a single setup. This is particularly beneficial for start-ups that need to prototype intricate designs without spending extra time or money on multiple setups. This flexibility also allows designers to explore more creative and functional designs, knowing the machine can handle the complexity.

Higher Accuracy

Accuracy is essential in prototyping to ensure that the final product performs as intended. 5-axis CNC milling reduces the need for multiple setups, saving time and ensuring higher accuracy by reducing the chances of human error. This high level of precision is critical for product development, where small deviations can lead to significant performance issues down the line. For start-ups, producing an accurate prototype the first time can save both time and money, allowing you to move quickly toward market launch.

Reduced Production Time

Time is money, especially for start-ups racing to bring a product to market. 5-axis CNC milling significantly reduces production time by allowing complex parts to be machined in a single setup. Traditional methods often require multiple setups and realignments, which increase the time it takes to produce a part. By consolidating these steps, 5-axis milling helps start-ups accelerate their product development timelines.

Cost Savings in the Long Run

While the initial cost of 5-axis CNC milling might seem high, the long-term cost savings can make it a more affordable option than expected. The ability to machine complex parts in fewer steps reduces the need for additional equipment, labor, and rework. All these contribute to lower overall production costs. These savings can add up over time for start-ups, making 5-axis CNC milling a smart investment for product development and production.

Versatility Across Industries

Start-ups across various industries can benefit from the versatility of 5-axis CNC milling. Whether you’re developing products for aerospace, medical devices, automotive, or consumer electronics, 5-axis machines can handle a variety of materials and part designs. This versatility means you don’t need to switch between different machining services for different projects.

How to Get Custom 5-Axis CNC Mill Service

Finding affordable 5-axis CNC milling services can be challenging for start-ups, but with the right approach, you can secure high-quality machining without breaking the bank. Here are some tips:

Research Service Providers

You should begin by researching multiple service providers, focusing on those with experience in 5-axis CNC milling. Look for providers who specialize in custom machining for start-ups and small businesses, as they are often more willing to offer flexible pricing and tailored solutions. Comparing providers based on their expertise, customer reviews, and capabilities will help you find a partner who can deliver high-quality parts at a reasonable price.

Compare Pricing Models

Different CNC service providers have different pricing models, so it’s important to compare them carefully. Some charge per hour of machine time, while others offer fixed pricing based on the complexity and volume of the project. Inquire about volume discounts or package deals for ongoing projects, as this can help reduce costs. Additionally, it’s wise to ask for detailed quotes upfront to avoid unexpected expenses.

Consider Local vs. Outsourcing

Depending on your start-up’s location, you might find it more affordable to work with a local CNC shop. Local providers can reduce shipping and logistics costs and may offer faster turnaround times. On the other hand, outsourcing to regions with lower labor costs like China, can be beneficial if budget is a major concern. Carefully consider the pros and cons of each option, balancing affordability with factors like communication and lead times.

Request a Prototype or Sample

Before committing to a large order, start-ups should request a prototype or sample from the service provider. This allows you to test the quality and accuracy of the machining before moving forward with full-scale production. Prototyping also allows start-ups to make any necessary design adjustments early in the process. This can save time and money in the long run.

Negotiate Contracts

Start-ups often have more bargaining power than they realize. Don’t be afraid to negotiate with service providers to secure better terms. This could include asking for discounts on bulk orders, lower rates for repeat business, or even bundled services such as design optimization or material sourcing. Many CNC providers are willing to work with start-ups to build long-term relationships, especially if they see potential for future growth.

Leverage Online Platforms

Several online platforms connect start-ups with CNC service providers, allowing you to compare prices, capabilities, and customer reviews. These platforms often provide instant quotes based on your design files, making it easier to budget for your project. Online resources can help you find the best service providers for their specific needs without relying solely on local shops.

Conclusion

5-axis CNC milling may initially seem expensive for start-up end users. However, it can be a cost-effective solution when the benefits are carefully weighed. From its ability to handle complex parts with high precision to its potential for long-term savings, 5-axis CNC milling offers start-ups the opportunity to innovate efficiently. Choosing the right service provider can help you leverage this advanced machining technology without overstretching your budgets.